Condensate Discharge Problems in Drying Machines

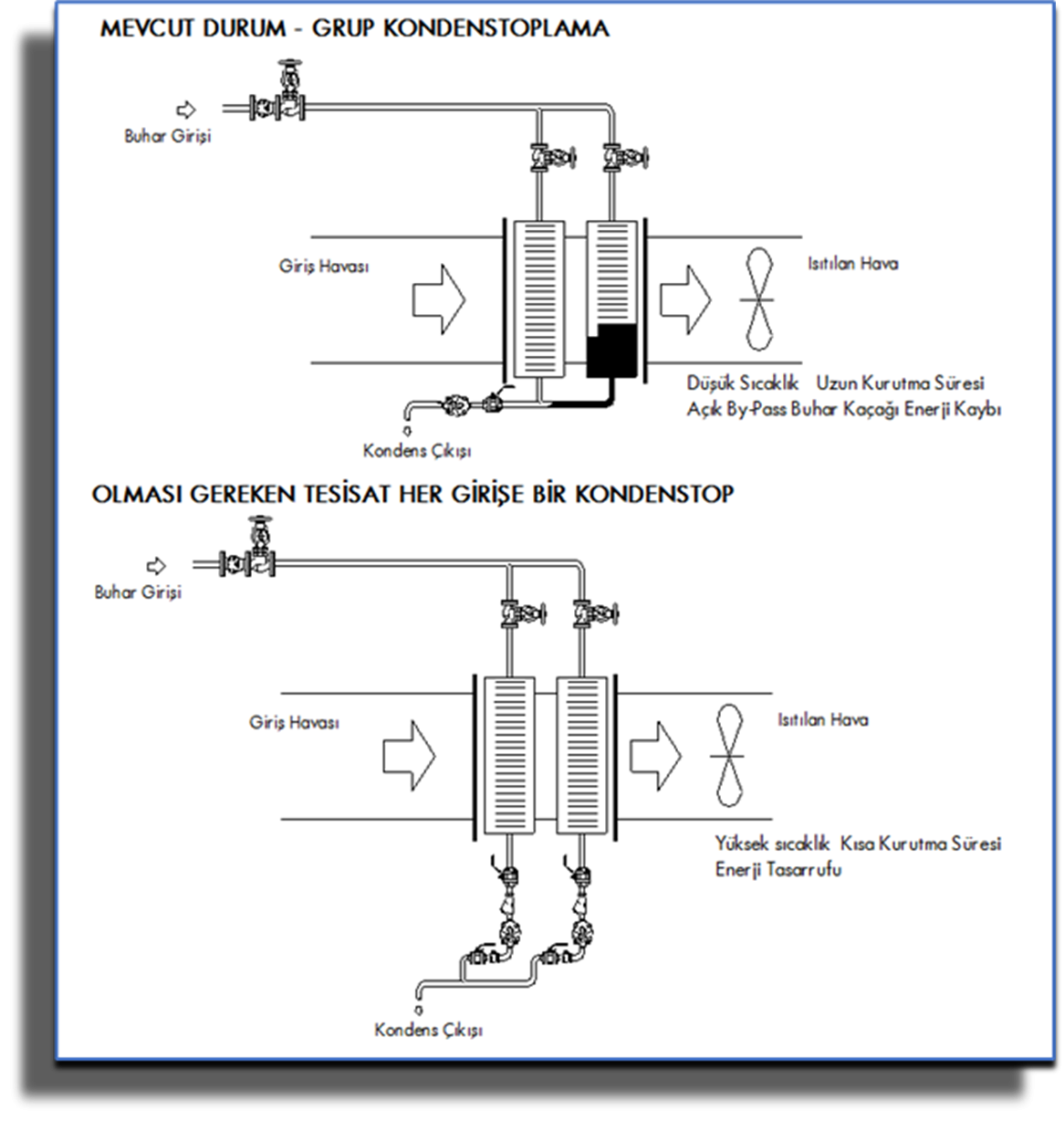

Group Steam Trap (Connection of a Single Steam Trap to Two Serpentines)

In some businesses, although there are two coil inlets in the dryers, their outlets are connected to a single steam trap by combining them. Steam traps connected in this way can only discharge condensate if condensate comes from both coils at the same time. However, if steam comes from one of the coils, the steam trap will close, and the condensate will not be discharged in the other coil and will accumulate, and first of all, there will be no healthy and rapid heating. Due to this condensate accumulation, the accumulated condensate will hit the steam trap with great force, causing the flange seals to burst and the steam trap to leak.

To explain in more detail; For example, consider a heat exchanger consisting of finned tube coils. The coils are heated by steam coming from a single line. Although it is possible to think of the entire machine part as a whole, in terms of condensate drainage, each section is a separate heat exchanger that collects the condensate. The amount of condensate formed varies from section to section due to the load differences between the coils.

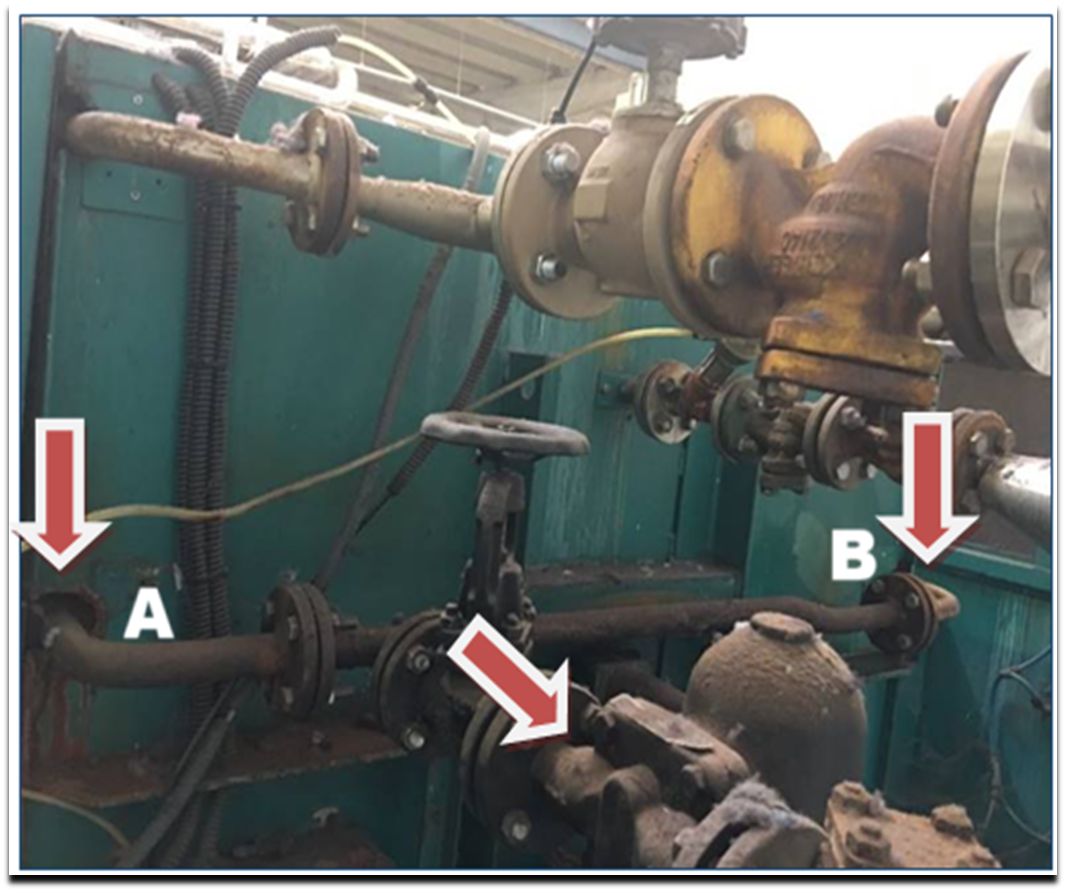

The first coil (B) typically has a higher load because it receives colder product, has a higher steam velocity due to suction, and is therefore at a relatively high pressure. In this case, the other coil (A) has a lower load and will enter the coil at a slightly lower pressure than the other coil. In such a case, the first coil will have a “short circuit” because the outlet pressure will be greater than the last coil.

We can explain this short circuit situation as follows; When the drainage points of different coils or machines with different pressures are connected to a single trap, the machine with the highest pressure (in this case Coil A) will block the condensate flow of the other. The coils that need the most condensate discharge (in this case B) will create water hammer.

The water hammer effect is very large and will cause your steam traps to break down. Leaking steam traps will also cause your condensate tank to “swell” and your feed water pumps to fail. For all these reasons, a separate steam trap must be installed on each coil.