Highest Cleanliness Level, Consistency, Safety, and High-Quality Components

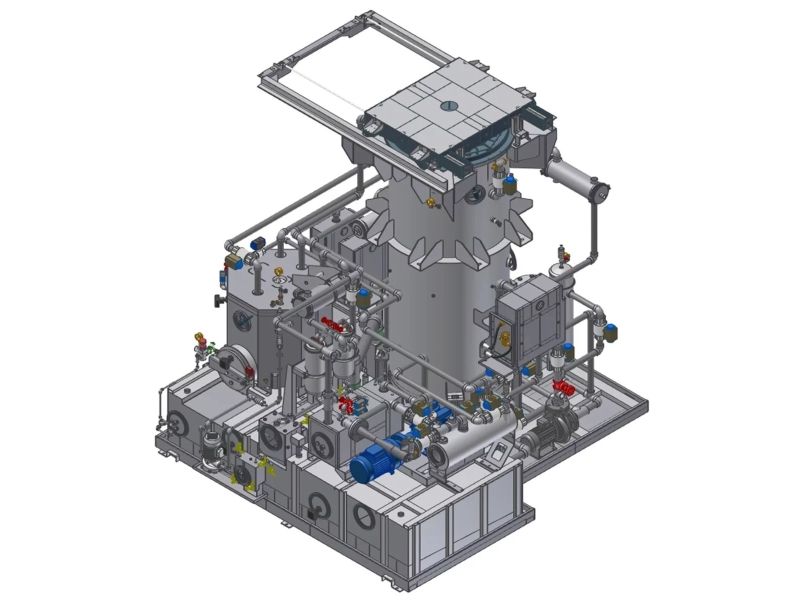

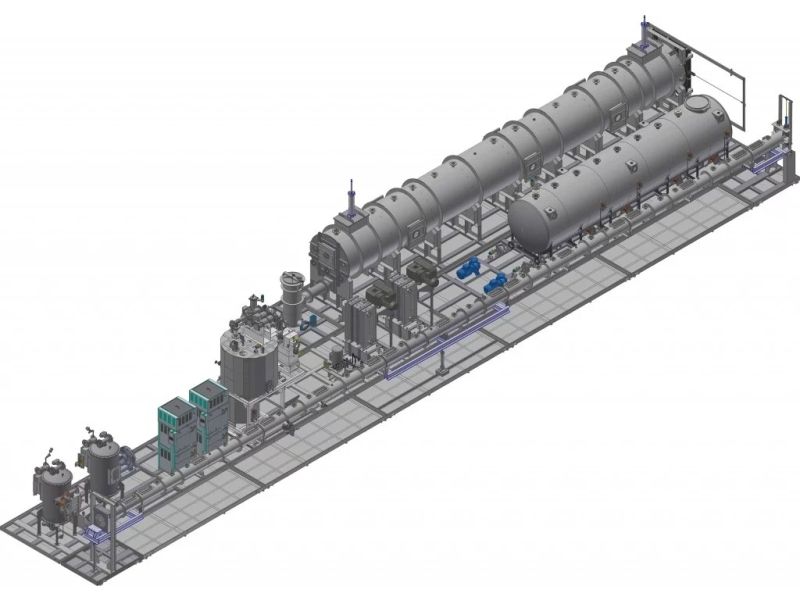

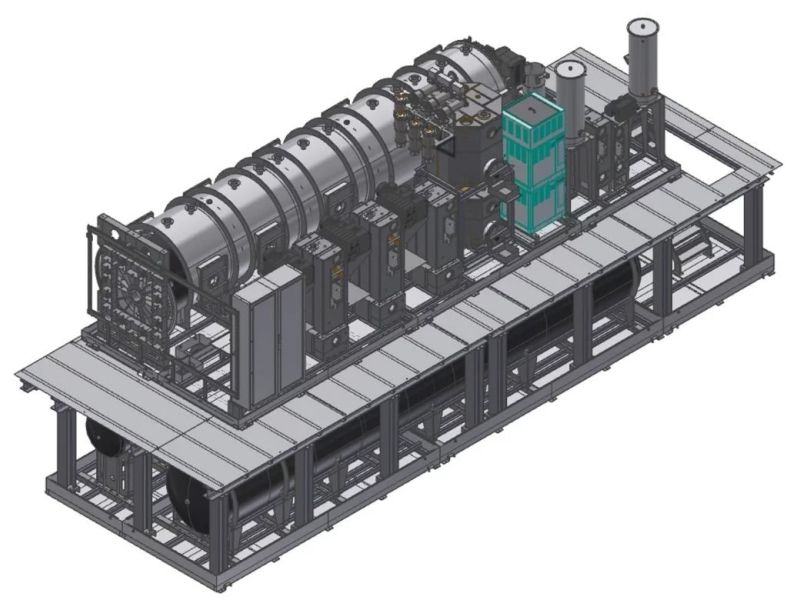

Special Industrial vacuum cleaning systems for tubes, coils, hollow bar and big metal components

Firbimatic has been working for several years alongside major manufacturers of tubes, coils and metal profiles to develop a wide range of industrial customized vacuum cleaning systems for the degreasing and for the surface treatment of all type of big components.

These wide range of components include piping production, hollow bars, metal profiles, sophisticated mechanical components, aerospace parts (including honeycomb), oil and gas components, medical tubes , power industry and defence big components.

The tubes, hollow bars, rods, profiles or components treated in our system can be made of the most different metals, such as:

- Stainless steel

- Aluminium

- Copper

- Nickel

- Brass

- Titanium

The Firbimatic customized vacuum cleaning systems can produce at an impressive hourly output (up to 3 cycles/h) as they are pre-arranged to work over 3 shifts and for more than 320 days a year, always insuring the compliance of the strictest internal cleaning parameters of the parts, (e.g. those set on EN 723 or ISO 16232).

Our customize cleaning and degreasing systems operate in full safety with the following typologies of solvents and liquids:

- Modified alcohols

- Aliphatic hydrocarbons

- Super stabilised Perchloroethylene

- Water and detergents

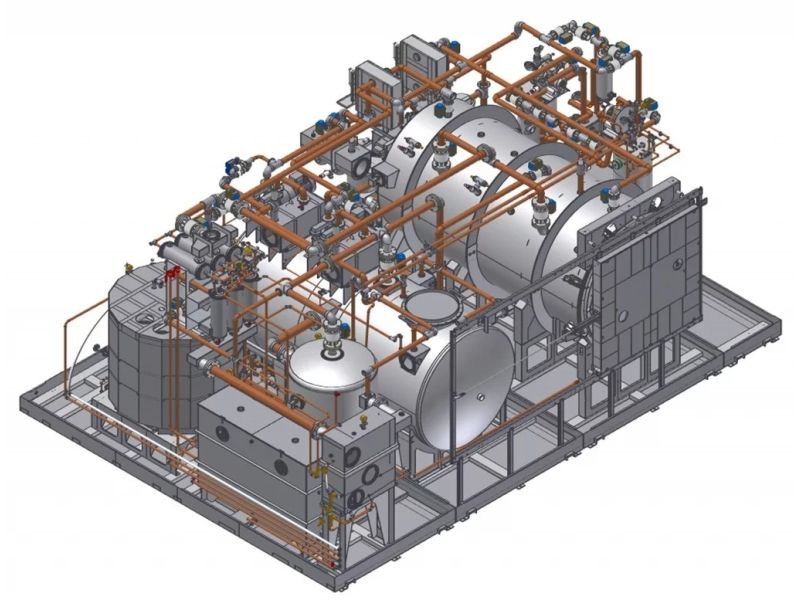

The operational principles of the vacuum cleaning systems which employ above solvents and liquids, are basically the same as that of standard systems, with the possibility to perform the cycle entirely under vacuum. At the same time, thanks to the modular design machine construction, the cleaning system can be adapted to the lay-out of the customer’s factory and can be integrated within existing production lines.

The main features of the industrial customized vacuum cleaning system

- Modular construction, specifically designed according to customer needs

- Cleaning and drying of parts inside a sealed chamber, thus avoiding any emission of towards the outside

- Highest cleanliness achievable thanks to the different cleaning phases that can be programmed and can be alternate at adjustable times:

Spraying by superior, lateral and lower bars

Immersion or half-immersion , with ultra-filtration and ultrasonics

High Pressure solvent injection flooding

Vapour-phase with direct solvent vapour

- The operator never comes in contact with the solvent or other toxic liquids, since the management of the machine take place automatically and without creating environmental problems to the operator with respect to a possible exposure to any residual emissions

- High quality manufacturing materials, like the usage of high grade stainless steel for all main machine subassemblies in contact with solvents or other hazardous liquids

- Waste minimization by continuous solvent regeneration inside the machine (Cont. distillation)

- Up to 50 % Energy saving by means of heat recovery system installed in the distiller

- Easy operation by proprietary Siemens PLC software. Machine operations and automatic periodical maintenance routines, electrical cabinet and system with data management and storage

The Cleaning Cycle of a Pipe vacuum degreasing machine

The operation cycle of pipe cleaning machine is totally automatic and it takes just one operator to load and unload the pipe bundles roughly every 20/40 minutes (depending on ID and length).

The machine is controlled by the PLC Siemens of the S7-1500 series, coupled either with an industrial PC or with the Siemens Touch-panel. All alarms and functions can be monitored and controlled remotely, thanks to the modem connection Siemens Gate Manager. This provides a clear picture of the working conditions of the system, which can inspected and trouble-shooted in real time remotely from the Firbimatic factory in Italy.

Sequence of phases during the cycle:

- Pipes/components are loaded inside the chamber, laid in an appropriate basket. Once the door hatch of the washing chamber is closed, the cycle starts with a prewashing phase in which hot liquid is sprayed by special ramps equipped with nozzles. The liquid is then re-circulated at high pressure so that to eliminate the contaminants from the outer surface of the pipes/profiles/components.

- Pipes/components are then soaked with hot liquid (temperature can be set up to a max. of 90 °C). During this phase, the liquid is re-circulated longitudinally along the chamber by an high-pressure pump in order to reinforce the washing effect. Optionally, it is available the alternated oscillation movement of the basket, aimed to substantially improve the internal cleaning of the pipes, even for diameters smaller than 1-2 mm.

- Also, in certain models, ultrasonics can be added to further reinforce the cleaning effect (option).

- The end of the two washing phases (external and internal) is followed by the direct vaporisation phase of the parts with solvent vapours coming from the distiller. This is the final touch and to prepare them for the drying phase.

- After the washing and rinsing, Pipes/components need to be dried. Drying phase involves the further reduction of the pressure inside the washing chamber, which determines the residual liquid on tubes to instantaneously evaporate. All liquid and solvent vapours are then recovered by re-condensation through a sequence of heat-exchangers.

In the specific case of cleaning of stainless steel Coils, (which in some cases they can be up to 3 km long and with an internal diameter of up to 0.5 mm), each coil end needs to be positioned and fixed to a suitable structure to allow high pressure solvent washing/rinsing to be recirculated inside, up to a pressure of 300 BAR.

Finally, in case of a perchloroethylene operated machine, the remaining solvent vapours in the chamber are forced through the active charcoal bed with the aim to reduce their concentration inside the washing chamber until the acceptable lower limit. The cycle of cleaning machine takes roughly 30 minutes or so, based on the inside diameter of the tubes/coils and on their quantity.

The solvent is continually regenerated by the two powerful continuously running stills that regenerate the solvent periodically.