How to Save Water in Laundromats?

Maximize Water Savings in the Professional Laundry Sector with PERMAK Machine

In an era where sustainability is no longer an option but a necessity, the professional laundry sector, including industrial, commercial and self-service laundries , is facing increasing pressure to reduce water consumption. As one of the largest water-consuming sectors, the laundry sector has the potential to save water, and this potential is seen as significant given the increasing global water stress and scarcity, as well as water quality issues.

Water is a finite resource, and its availability is threatened by factors such as climate change, population growth and industrial demands. In professional laundry operations, water plays a vital role in achieving the cleanliness and hygiene standards expected by customers and regulatory bodies. However, the traditional textile washing process is quite water intensive; washing machines consume between 10 and 15 litres of water per garment, while tunnel washers consume between 4 and 7 litres per kilogram, depending on the machine used and the type of fabric being washed.

For industrial and commercial laundries that process large volumes of textiles daily, this creates a huge water footprint. The environmental impact is further magnified by the energy required to heat the water and run finishing machines such as irons and dryers . Therefore, water conservation is a critical component of broader sustainability efforts. Furthermore, reducing water usage can provide direct cost savings to businesses, positively impacting the profitability of businesses in the sector.

Water Saving Strategies with PERMAK Machine in the Professional Laundry Sector

1. Invest in PERMAK High-Efficiency Commercial Laundry Equipment

One of the most effective ways to reduce water consumption is to switch to high-efficiency washing machines from PERMAK . These machines are designed to use significantly less water per cycle without compromising cleaning performance. Modern commercial washers often feature advanced technology, such as weighing systems that adjust the amount of water and chemicals according to the load size and level of dirt.

PERMAK brand tunnel washers used for industrial laundries already increase water saving by their nature. These tunnels recycle water from the rinse and spin cycles and reuse it in the pre-wash and wash stages. This internal recycling significantly reduces total water consumption. In addition, tunnels can be equipped with filtering options in various tanks and heat exchangers to reuse the energy contained in the water. In addition, water recycling systems are available to make the water usable again.

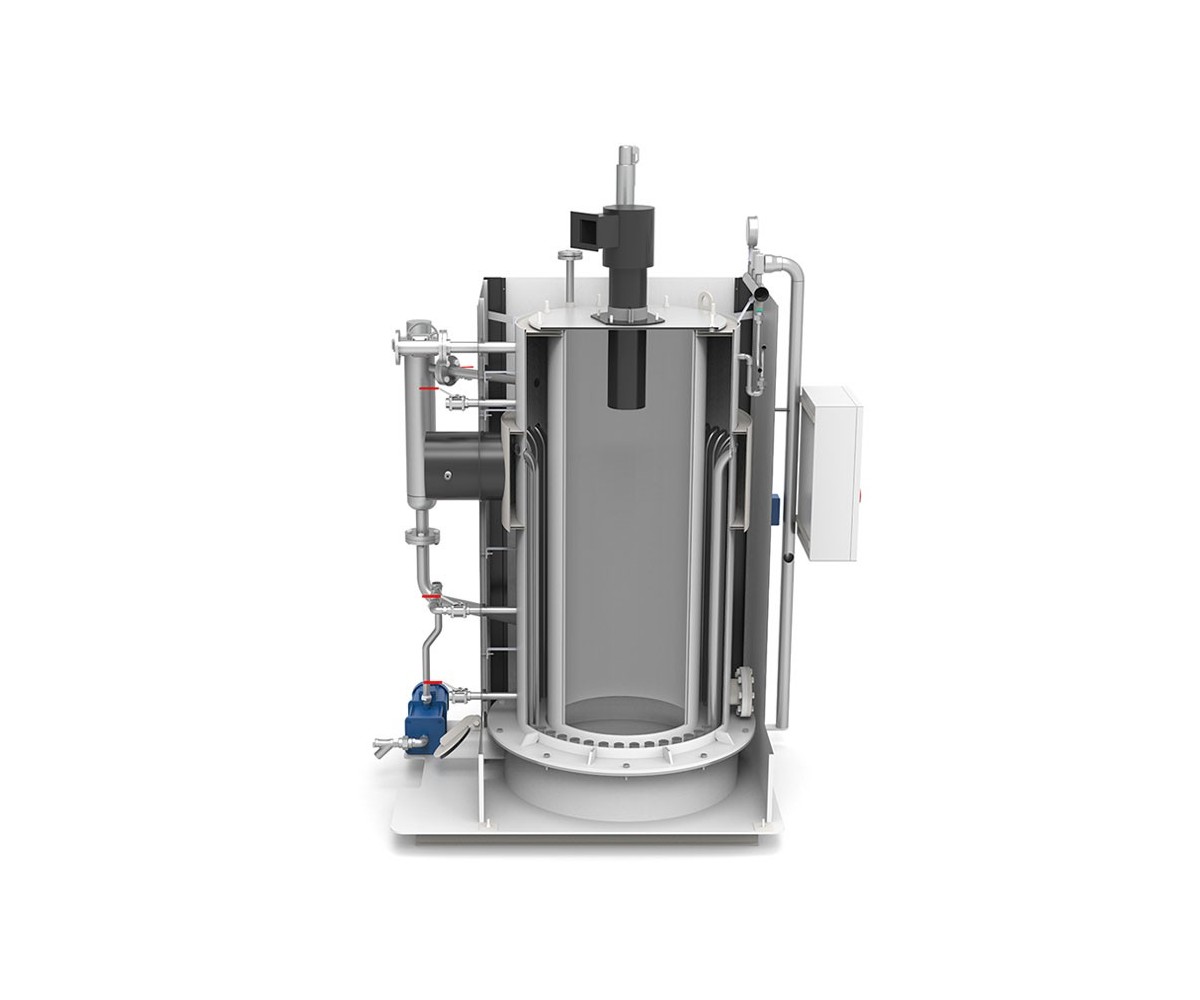

2. Implement PERMAK Water Recycling Systems

PERMAK water recycling systems reclaim wastewater from laundry processes and process it for reuse in subsequent wash cycles. This not only reduces total water consumption, but also reduces the amount of wastewater that needs to be processed before discharge. With the integration of PERMAK water recycling systems, laundries can save up to 85% of their water, which means significant cost savings in the long term. For effective water management, it is important to include microfiltration solutions, including the capture of microplastics and organic microparticles.

3. Optimize Wash Cycles with PERMAK

Creating wash cycles suitable for specific types of loads with PERMAK can make a significant difference in water savings. For example, lightly soiled items do not require as much water and detergent as heavily soiled fabrics. Laundries can minimise water waste by adjusting cycle times, water levels and rinse processes according to the needs of each load.

4. Provide Regular Maintenance and Training with PERMAK

Regular maintenance of washing machines is essential to ensure they are operating at peak efficiency. Leaks in pipes or equipment can lead to significant water losses over time. Permak proactive maintenance services prevent these losses and maintain optimal water use efficiency.

Effective water conservation in the laundry industry requires not only advanced technology, but also comprehensive training and consulting services. It is essential to provide ongoing training to laundry staff on water conservation best practices. In addition, water efficiency and recycling solutions must be adapted with consulting services tailored to the specific needs of each laundry operation. When customized solutions are combined with in-depth training on optimal processes, laundries can make significant improvements in water conservation.

Beyond the environmental benefits, there is a strong business case for saving water in the professional laundry industry. With water costs continuing to rise, reducing water consumption means lower bills and directly impacts the bottom line. Additionally, many jurisdictions offer incentives or tax breaks to businesses that invest in water-saving technologies, further reducing the cost of these upgrades.

Additionally, adopting sustainable practices attracts environmentally conscious customers, allowing a business to stand out in a competitive market. In an industry where efficiency and cost-effectiveness are at the forefront, the financial and operational benefits of water conservation are undeniable.

The professional laundry industry should prioritize water conservation as part of its operational strategy. By investing in high-efficiency equipment from PERMAK, installing water recycling systems, optimizing wash cycles and promoting a culture of sustainability, you can significantly reduce the water footprint of your laundries. These efforts not only contribute to environmental responsibility, they also provide significant financial benefits, making water conservation a win-win for both the planet and the bottom line. With the demand for sustainability increasing, it’s time for the laundry industry to take action.